Rotary Grinding: Making Parts Smooth, Flat, and Accurate

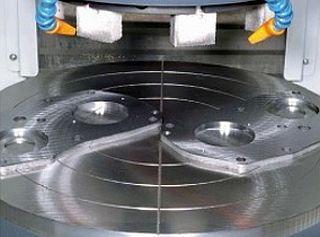

Take a look at any large, flat-machined part. See that nifty cross-hatched pattern? Rotary grinding produced that surface. What's more, it most likely did so quickly and cost-effectively. So, what is rotary grinding best suited for? The folks at Kent USA answer that question.

The rotary grinding process has been around for more than 100 years. Old-timers call it Blanchard grinding. The correct term is rotary surface grinding or just rotary grinding. Whatever you call it, rotary grinding was first commercialized in the early 1900s.

And for the reasons you're about to read, it soon became the go-to technology for anyone needing smooth, accurate metal, glass, and ceramic parts.

Rotary Grinding Basics

How do rotary surface grinders work?

In a nutshell, they consist of a rotating worktable with a grinding wheel mounted above. A magnetic chuck clamps the part (or many small parts) to the table, which spins beneath the grinding wheel in the opposite direction. This action makes for efficient material removal.

VIDEO: Kent USA RGH-1000A Rotary Grinder

Furthermore, it delivers the flat, cross-hatched pattern mentioned earlier.

Who Uses Rotary Grinding?

Simply put, anyone who needs to make big parts very flat, very quickly uses rotary grinding.

Stamping houses, for instance, use it to ensure that die sets are perfectly smooth and parallel. Then there are automakers, which send clutch plates and brake rotors by the gazillions through rotary grinding machines.

Similarly, electric vehicle (EV) battery makers use this highly mature process anywhere large, smooth surfaces are needed.

So do electronics and semiconductor manufacturers, who use rotary grinding for tooling and equipment. Add to this aerospace and medical device companies, machine tool builders, tool and die makers, and many others. It's a long list, and as the reshoring boom continues, it is expected to get longer.

Several styles of rotary grinding machines are available.

For instance, the KENT USA® KRGH-series uses a vertical grinding wheel arrangement. It's not unlike what is found on a surface grinder. What's different is the rotating table sitting underneath. It carries a magnetic chuck to securely grip metal workpieces, spinning them at speeds up to 200 rpm.

Conversely, the KENT USA® CHS-series and RGV-series rotary grinders have a horizontal grinding wheel. Each supports heavier metal removal and larger workpieces. The RGV-1200A, for instance, handles workpieces up to 47" in diameter and weighs more than ten tons.

Whatever series, they all feature a class FC30 Meehanite casting for superior rigidity. Color touchscreen control displays simplify operation, while high-precision bearings and hardened slideways ensure long life and consistently accurate parts, according to the company.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::